Hosch

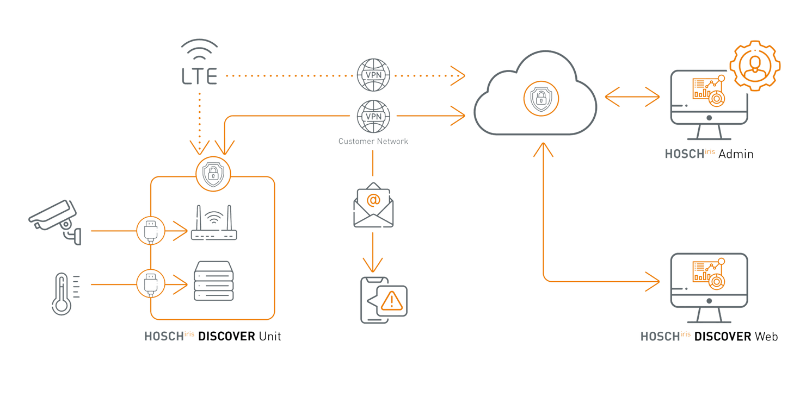

In collaboration with Hosch, we provide insights on current and future conditions of specific locations on a belt, like splices, to plan inspections and maintenance actions in time.

Cooperation for your success

Splaice is a combination of mechanical engineering excellence by HOSCH Group and advanced analytics by Predge. This solution will keep your operation running and prevent critical splice failures from happening.

Predge industrial AI solution

Edge AI and machine learning technology

Industrial AI assisted by expert domain knowledge on splice degredation

Fully automated analytics

Track health

Decision support

Safe & Efficient

How do we achieve this?

By learning belt finger prints from motion signals, pinpointing splice locations and deterioration in real-time.

Translating data into customized decision support aligned with your operational needs.

Stay ahead of the failure! Choose SplAIce and increase the availability of your operation.

Splaice failures are the one most common reason for reduced availability disrupting material flow of industrial conveyor belt systems.

3 stage implementation

Data acquisition & data integration

Hardware installed & data online

Processing & analytics

Refined AI trained with reference data applied

Validation & optimisation

Accuracy & operational value creation proven

Technology proven at RWE Germany

After several severe damages to the belt splices of two highly stressed conveyors, we checked the market for a solution to monitor the belts and splices. With HOSCH & Predge we implemented the solution we were looking for in a fast an collaborative way. The HOSCHiris DISCOVER + splaice system is a simple and reliable way to be informed at all times about the belt splices and the condition of the conveyor belt to detect the smallest deterioration at a very early stage, in order to avoid production losses.